The CRD 3-40 is the mechatronic system that enables to crack a combination lock by exploiting. It was built by Ross Aiken as the class group project for ECE453 - Embedded Microprocessor System Design at the University of Wisconsin - Madison.

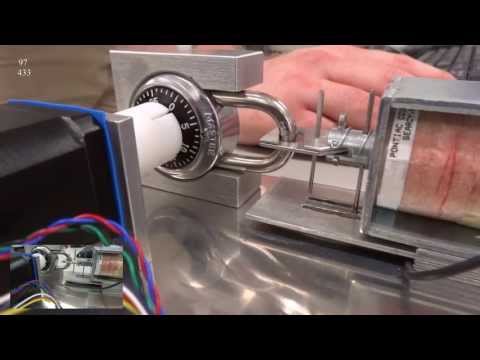

The shackle on the padlock is pulled by a solenoid. The position of the dial is accurately determined by an encoder and the stepper motor turns the dial on the lock. The graphical user interface allows to enter known digits, then the system tries to open the lock prioritizing them. The implemented algorithm to figure out the combination is discussed here. The CRD 3-40 is sensitive enough to find all of the 'sticky spots', using them to decrease the number of possible combinations from 64,000 to 80. It consists of a ZedBoard, a custom-designed PCB, a solenoid, a stepper motor, an encoder, and, of course, a lock.

The authors suggest the following further optimizations that could be done in this mechatronics project:

1) Back-dialing the second digit - After dialing in the first digit once, all possible second and third digits can be run if you spin the middle dial backwards at the right times.

2) Decreasing the solenoid hold time - With an improved mounting setup, the hold time on the solenoid could be reduced.

3) Increasing the spin speed - Once again with an improved mounting setup, the spin speed could be improved (as it stands right now, the pressure fit on the dial causes excessive friction between the dial and the case, and spinning too much faster could cause permanent damage to the lock).

Comments