Do you think that gear mechanisms, which intermesh and rotate, are solely man-made? You were right until the research results were published. Scientists from the University of Cambridge revealed functioning biomechanical gears for the first time in the flightless planthopper insect Issus. The gears are used in ballistic jumping movements of the insect.

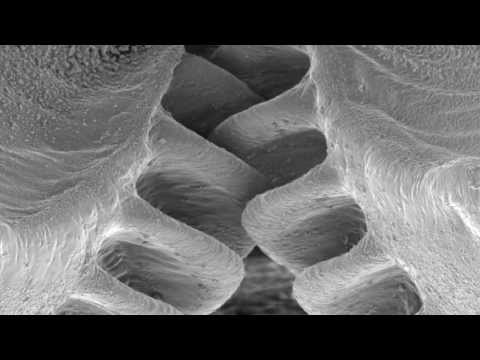

Follow the University of Cambridge website the gears in the Issus hind-leg bear remarkable engineering resemblance to those found on every bicycle and inside every car gear-box. Tooths of gears are rounded at the point it connects to the gear strip such as bike gears. It is a shock-absorbing mechanism to stop teeth from shearing off. Each gear strip is around 400 micrometres long and had both sides of the gear in each leg containing 10 to 12 teeth, which gives a gearing ratio of 1:1.

Unlike man-made symmetric shape gears which allow to work in both rotational directions, each gear tooth of insect's gear is asymmetrical and curved towards the point where the cogs interlock. It is because the Issus gears are only powering one way to launch the animal forward. The teeths on the opposing hind-legs of insect lock together and ensure almost complete synchronicity in leg movement. The synchronicity ensure, that the legs move within 30 ‘microseconds’ of each other. You can ask, why insect need such as biomechanical gear mechanism. The evolution 'shaped it' for the powerful jumps that are Issus’s primary mode of transport and capabilities of gear mechanism would be impossible to obtain using insect's nervous system. Lead author Professor Malcolm Burrows, from Cambridge’s Department of Zoology said:

This precise synchronisation would be impossible to achieve through a nervous system, as neural impulses would take far too long for the extraordinarily tight coordination required.To start the jump, Issus send nerve signals to its muscles to produce force to starts to propel legs. Even miniscule discrepancies in synchronisation between the velocities of both legs would result deviation from the path of movement. Biogear allow Issus just to send nerve signals to its muscles to produce roughly the same amount of force to starts to propel one leg. Then if one leg starts to propel the jump the gears will interlock, creating absolute synchrony and the insect can move to its intended destination. So such a solution solve a complex problem that the brain and nervous system can’t. Co-author Gregory Sutton, now at the University of Bristol said:

These gears are not designed; they are evolved - representing high speed and precision machinery evolved for synchronisation in the animal world.

Comments